Multi Point Full Body Bottom Cake Discharge

Price 25000000 INR/ Set

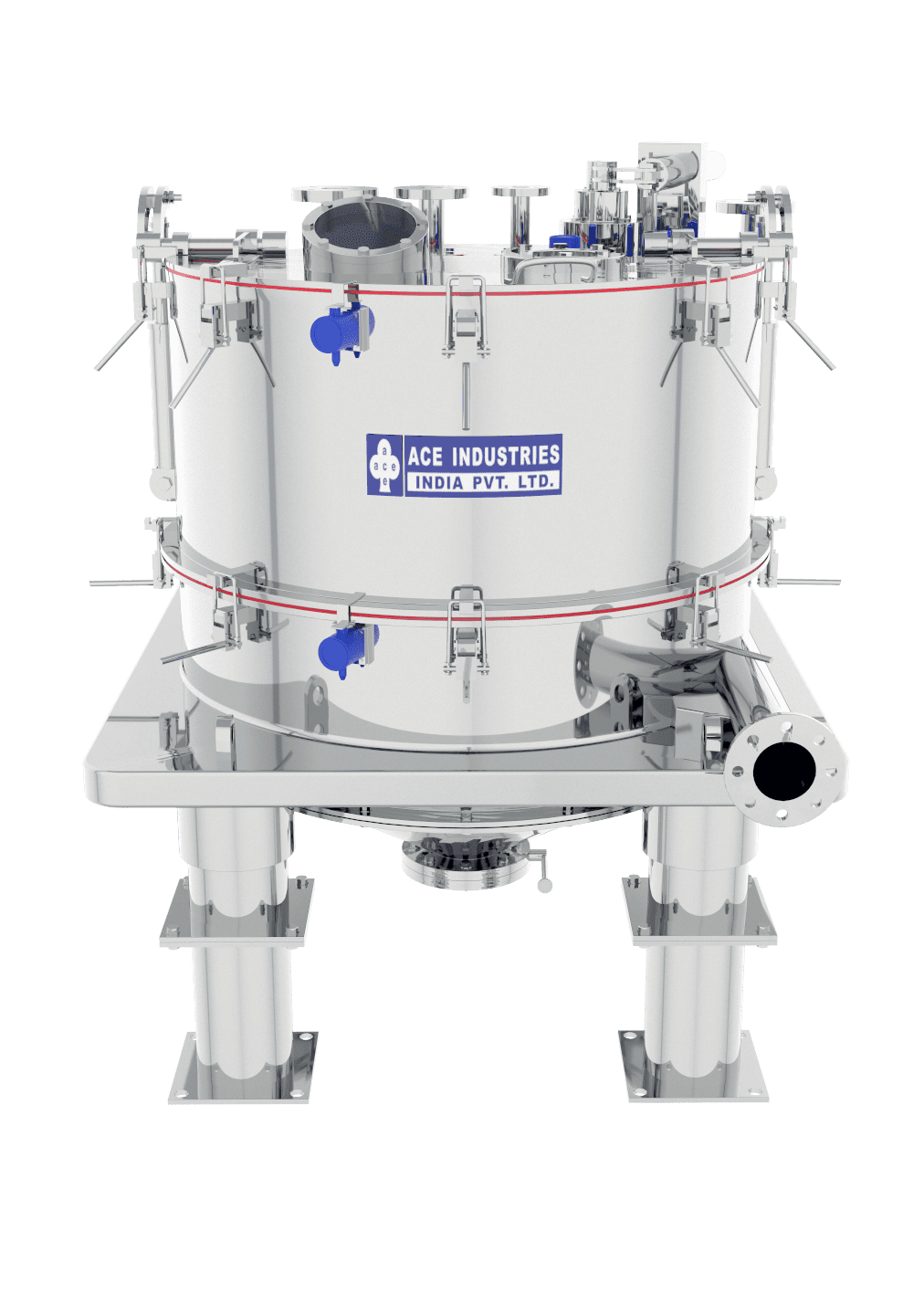

Multi Point Full Body Bottom Cake Discharge Specification

- Type

- Batch Type

- Material

- SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 20 Horsepower (HP)

- Weight (kg)

- 3500 Kilograms (kg)

- Color

- SS

- Warranty

- 1 Year

Multi Point Full Body Bottom Cake Discharge Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Extra at actual

- Certifications

- DQ, IQ

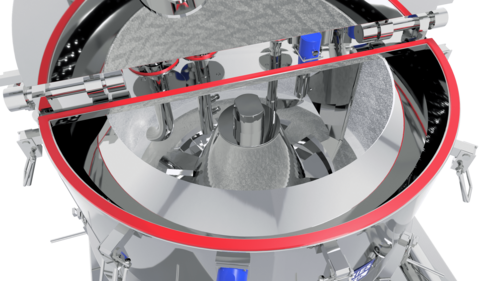

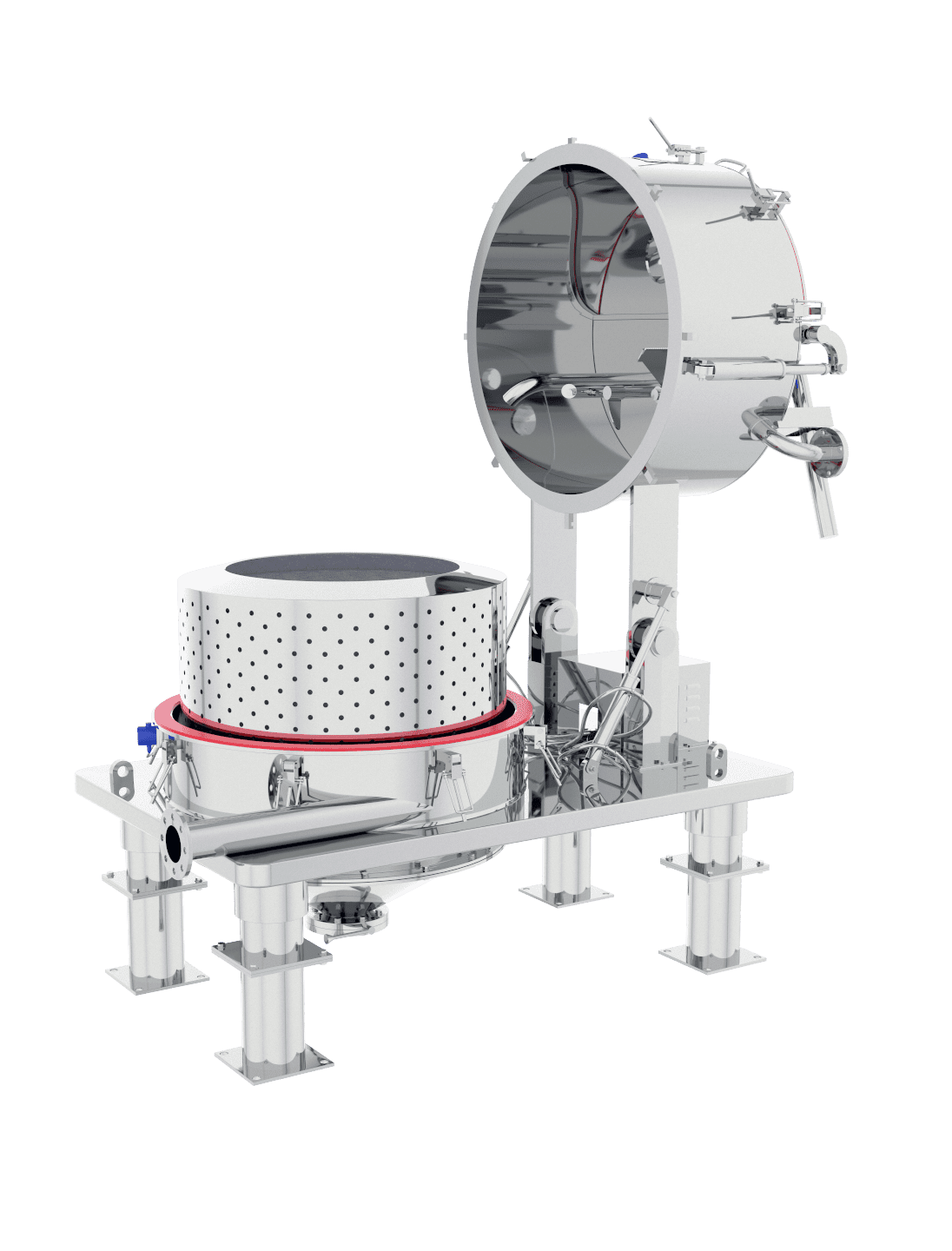

About Multi Point Full Body Bottom Cake Discharge

Multi Point Full Body Bottom Cake Discharge refers to a method or system for removing solid materials or a cake-like substance from a container, vessel, or filtration system at multiple locations simultaneously or at multiple points within the container. This approach is often used in various industrial processes to enhance efficiency and ensure uniform removal of the solid material. Here's a more detailed explanation:

1. Solid Material Accumulation: In industrial processes such as filtration, sedimentation, or centrifugation, solid materials or particles can accumulate at the bottom or on the filter medium, forming a cake.

2. Multiple Discharge Points: Multi-point cake discharge involves the use of several discharge points distributed across the bottom or within the vessel. These discharge points can be strategically located to cover a larger surface area, ensuring more uniform cake removal.

3. Enhanced Efficiency: By utilizing multiple discharge points, the removal of the cake material can be more efficient and faster compared to systems with a single discharge point. This helps maintain the overall efficiency of the separation or filtration process.

3. Applications: Multi-point cake discharge is applied in various industries where solid-liquid separation is critical. Examples include wastewater treatment, chemical processing, mining, and food and beverage production.

4. Equipment: Different types of equipment and mechanisms can be designed for multi-point cake discharge. This can include systems with multiple discharge valves, conveyor belts, or other mechanisms that facilitate the simultaneous removal of solid material from various points within the vessel.

5. Automation: Automation is often integrated into multi-point cake discharge systems to control the process and optimize the removal of the cake material. Automation can help regulate the discharge rate, timing, and sequence for efficient operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machinery Category

Mass Mixer

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Weight (kg) : 3500 Kilograms (kg)

Control System : Frequency Speed Control

Drive Type : Electric

Vibro Shifter

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Weight (kg) : Machine to Machine Varry Kilograms (kg)

Control System : Frequency Speed Control

Drive Type : Electric

GST : 27AAICA7458F1ZG

|

Ace Industries (India) Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry