Mass Mixer

Price 1000000 INR/ Piece

Mass Mixer Specification

- Type

- Batch Type

- Material

- SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Weight (kg)

- 3500 Kilograms (kg)

- Color

- SS

- Warranty

- 1 Year

Mass Mixer Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA)

- Supply Ability

- 8 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Extra at actual

- Main Export Market(s)

- Asia, South America

- Certifications

- DQ, IQ

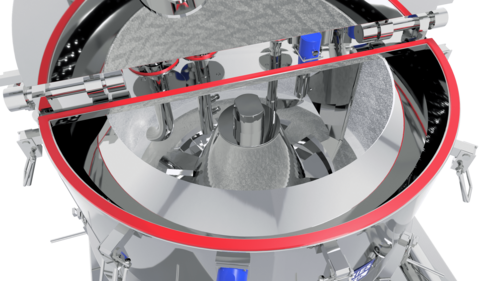

About Mass Mixer

A mass mixer is a sort of modern blending hardware utilized in different enterprises, including drugs, food handling, and compound assembling. Its basic role is to mix or blend powdered or granular materials in mass to accomplish a homogeneous combination. Mass mixers are generally utilized in the creation of drug tablets, dry food items, beauty care products, and other powdered or granulated materials.

Key highlights of a mass mixer include:

1. Blending Chamber: Mass mixers regularly have a huge blending chamber where the materials are stacked for mixing. The chamber might have a tapered or Angular plan to work with effective blending.

2. Blending Sharp edges: Inside the blending chamber, there are uncommonly planned edges or instigators that pivot to blend the materials. These cutting edges can be paddle-formed, strip molded, or different setups, contingent upon the particular prerequisites of the blending system.

3. Material Stacking and Release: Mass mixers frequently have a top-stacking configuration, permitting administrators to effectively add materials to the blending chamber. Subsequent to blending, the mixed material is released through a base or side outlet.

4. Control Framework: Numerous cutting edge mass mixers accompany progressed control frameworks that permit administrators to change the blending speed, blending time, and different boundaries to accomplish the ideal mix consistency.

5. Material Dealing with: Mass mixers are intended to deal with a large number of materials, including dry powders, granules, and, surprisingly, a few semi-fluid materials.

The essential benefits of utilizing a mass mixer include:

1. Productive Blending: Mass mixers can effectively mix huge amounts of materials, guaranteeing uniform dispersion of fixings.

2. Efficient: They can essentially lessen blending times contrasted with manual or bunch blending techniques.

3. Cleanliness and Wellbeing: In ventures like drugs and food handling, mass mixers are intended to meet severe cleanliness and security guidelines to forestall tainting.

4. Adaptability: Mass mixers can be utilized for both limited scope and huge scope creation processes, making them flexible hardware in different enterprises.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Machinery Category

Multi Point Full Body Bottom Cake Discharge

Price 25000000 INR / Set

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Color : SS

Material : SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

Type : Batch Type

Vibro Shifter

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Color : SS

Material : SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

Type : Batch Type

GST : 27AAICA7458F1ZG

10, 11, 12 & 14, Alpine Industrial Estate, Marol Military Road, Andheri (E),Mumbai - 400059, Maharashtra, India

Phone :08045802744

|

Ace Industries (India) Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry