Rotocone Vacuum Dryer

Price 500000.00 INR/ Liter

Rotocone Vacuum Dryer Specification

- Type

- Batch Type Operation

- Material

- SS 316, SS 304, Antistatic Halar Coated, Hastelloy

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Weight (kg)

- 2000 Kilograms (kg)

- Color

- SS

- Warranty

- 1 Year

Rotocone Vacuum Dryer Trade Information

- Minimum Order Quantity

- 1 Liter

- Supply Ability

- 8 Liters Per Week

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Extra at Actual

- Certifications

- DQ, IQ

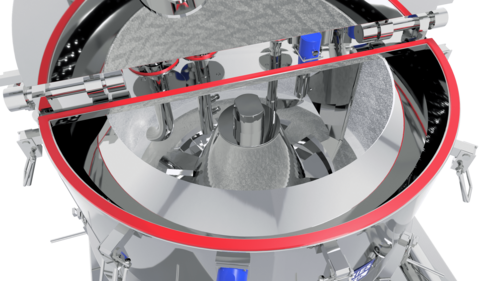

About Rotocone Vacuum Dryer

A Rotocone Vacuum Dryer is a particular kind of modern drying gear utilized for drying materials under vacuum conditions. It is otherwise called a Rotational Cone Vacuum Dryer or a Twofold Cone Vacuum Dryer. This dryer is usually utilized in the drug, synthetic, food, and other cycle enterprises for the drying of intensity delicate materials and substances that might be inclined to oxidation or corruption when presented to air at high temperatures.

Here are the critical highlights and parts of a Rotocone Vacuum Dryer:

1. Cone-Molded Vessel: The essential part of the dryer is a cone-formed vessel with a pivoting fomenter or a cone-molded coat for warming or cooling. The cone shaped shape considers productive blending and drying of the materials.

2. Vacuum Framework: The dryer works under decreased tension or vacuum conditions. A vacuum siphon is utilized to make and keep up with the vacuum inside the vessel. Working under vacuum decreases the limit of fluids, taking into account gentler drying at lower temperatures.

3. Warming and Cooling Coat: The vessel is furnished with a warming and cooling coat that can be utilized to control the temperature of the material being dried. Steam or boiling water is commonly circled through the coat for warming, while cold water or a cooling medium is utilized for cooling.

4. Fomenter or Turning Cone: The instigator or pivoting cone inside the vessel is liable for blending and persistently moving the material during the drying system. This development guarantees in any event, drying and keeps material from adhering to the vessel walls.

5. Dissolvable Recuperation Framework: Some Rotocone Vacuum Dryers might have a dissolvable recuperation framework to catch and consolidate solvents or unstable substances that vanish during the drying system. This can be fundamental in ventures where dissolvable recuperation is significant for cost investment funds and ecological reasons.

6. Control Framework: Present day Rotocone Vacuum Dryers are furnished with cutting edge control frameworks to screen and change boundaries, for example, temperature, vacuum level, and instigator speed to improve the drying system.

7. Security Elements: Wellbeing highlights, for example, pressure help valves and sensors for temperature and tension are consolidated to guarantee the protected activity of the dryer.

Rotocone Vacuum Dryer Uses:

1. Drug Industry: Rotocone Vacuum Dryers are broadly utilized in the drug business to dry substances like anti-infection agents, nutrients, natural concentrates, and other dynamic drug fixings (APIs). These materials are in many cases delicate to intensity and dampness, settling on vacuum drying an optimal decision to safeguard their quality.

2. Compound Industry: In the synthetic business, Rotocone Vacuum Dryers are utilized to dry a great many synthetic substances, including specialty synthetics, intermediates, and fine synthetic compounds. Numerous synthetic responses require exact command over temperature and tension, which can be accomplished utilizing these dryers.

3. Food Handling Industry: The food business involves Rotocone Vacuum Dryers for applications, for example, drying products of the soil powders, dairy items, and different food fixings. Vacuum drying keeps up with the flavor, variety, and dietary benefit of food items.

4. Home grown and Nutraceutical Industry: Natural concentrates and nutraceutical items frequently contain heat-delicate mixtures that can be harmed by high temperatures. Rotocone Vacuum Dryers are utilized to delicately dry these materials while saving their therapeutic properties.

5. Beauty care products and Individual Consideration Items: Beauty care products and individual consideration items, including powders, creams, and salves, can be dried utilizing Rotocone Vacuum Dryers to keep up with their consistency and viability.

6. Agrochemical Industry: The agrochemical business utilizes these dryers to deal with pesticides, manures, and other horticultural synthetic substances that might be delicate to intensity and stickiness.

7. Specialty Materials: Rotocone Vacuum Dryers are reasonable for drying specialty materials, for example, superabsorbent polymers, high level pottery, and impetuses.

8. Minerals and Mining: at times, these dryers are utilized to deal with minerals and metals, particularly when there is a need to control the drying system under vacuum conditions to keep away from oxidation or other substance responses.

9. Ecological Remediation: They can be utilized for drying and handling materials in natural remediation projects, for example, drying defiled soil or slop to decrease squander volume.

10. Innovative work: Rotocone Vacuum Dryers are likewise used in innovative work research facilities for pilot-scale drying tests and for drying little amounts of important or touchy materials.

FAQ:

1. What is a Rotocone Vacuum Dryer, and how can it work?

Ans: A Rotocone Vacuum Dryer is a modern drying gear that works under vacuum conditions to dry intensity delicate and fragile materials. It comprises of a cone-formed vessel with a pivoting instigator inside. The vacuum decreases the limit of fluids, considering delicate drying at lower temperatures.

2. What sorts of materials can be dried utilizing a Rotocone Vacuum Dryer?

Ans: Rotocone Vacuum Dryers are reasonable for drying a large number of materials, including drugs, synthetic compounds, food items, natural concentrates, beauty care products, and the sky is the limit from there. They are particularly valuable for heat-touchy and dampness delicate materials.

3. What are the upsides of utilizing a Rotocone Vacuum Dryer?

Ans: The benefits incorporate delicate drying at lower temperatures, diminished chance of material corruption, safeguarding of item quality, and the capacity to control the drying system under vacuum conditions.

4. How does the vacuum framework function in a Rotocone Vacuum Dryer?

Ans: A vacuum siphon is utilized to make and keep a vacuum inside the dryer vessel. This decreases the strain, brings down the edge of boiling over of fluids, and speeds up the dissipation of dampness from the material being dried.

5. Might Rotocone Vacuum Dryers at any point deal with enormous scope creation?

Ans: Indeed, Rotocone Vacuum Dryers are accessible in different sizes to oblige both research center scale and modern scale creation needs. They are utilized in pilot plants and creation offices.

6. What wellbeing highlights are ordinarily integrated into these dryers?

Ans: Security highlights might incorporate tension alleviation valves, temperature and strain sensors, interlocks, and alerts to guarantee safe activity and forestall mishaps.

7. Are there varieties in Rotocone Vacuum Dryers in view of industry-explicit necessities?

Ans: Indeed, there are tweaked Rotocone Vacuum Dryers intended for explicit businesses, for example, drug grade models that meet tough administrative necessities.

8. How might I control the drying system in a Rotocone Vacuum Dryer?

Ans: Current Rotocone Vacuum Dryers accompany progressed control frameworks that permit you to screen and change boundaries, for example, temperature, vacuum level, and instigator speed to upgrade the drying system.

9. What are some normal upkeep necessities for these dryers?

Ans: Standard support might incorporate really looking at seals and gaskets, greasing up moving parts, assessing the vacuum framework, and cleaning the inside to forestall tainting.

10. Might Rotocone Vacuum Dryers at any point be utilized for dissolvable recuperation?

Ans: A few models might have dissolvable recuperation frameworks to catch and gather solvents or unpredictable substances that vanish during the drying system, which can be fundamental in ventures where dissolvable recuperation is significant.

11. Are there any ecological contemplations while utilizing Rotocone Vacuum Dryers?

Ans: Involving a vacuum in the drying system can decrease energy utilization and discharges contrasted with conventional drying strategies, making it all the more harmless to the ecosystem in specific cases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machinery Category

Mass Mixer

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : 3500 Kilograms (kg)

Color : SS

Control System : Frequency Speed Control

Warranty : 1 Year

Multi Point Full Body Bottom Cake Discharge

Price 25000000 INR / Set

Minimum Order Quantity : 1 Piece

Weight (kg) : 3500 Kilograms (kg)

Color : SS

Control System : PLC Control

Warranty : 1 Year

Vibro Shifter

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : Machine to Machine Varry Kilograms (kg)

Color : SS

Control System : Frequency Speed Control

Warranty : 1 Year

GST : 27AAICA7458F1ZG

|

Ace Industries (India) Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry